What payment methods do you accept?

We currently accept the following payment methods - Bacs, Electronic Bank Transfer, World pay. Please note we do not accept cheques or PayPal.

How long does delivery take?

Generally our delivery lead times are between 1 and 5 days, although this does vary depending on the shipping location. Bespoke orders can also alter lead times depending on certain specifications. For more information on our lead times, or to ascertain a set lead time please call +44 (0) 1773 763134 or email info@fourdrubber.com

How much are your products?

As a white label company, many of our products vary depending on the client specification. Although we do offer standard products and packaging options, we do not list these on our website as again prices can vary depending on batch ordering and locations. If you are looking to obtain a price for any of our products, please email info@fourdrubber.com or call +44 (0) 1773 763134 and we will be happy to assist.

How is rubber manufactured?

Rubber is manufactured in various ways depending on the application it is to be used for.

Four D manufacture a range of natural rubber, latex and synthetic products, each in varying controlled environments. See our Four D technology page for more information on our processes.

What’s the difference between natural rubber, natural rubber latex and synthetic rubber?

Natural rubber is the outcome of dried natural rubber latex which has been compounded and processed. The chemical structure of natural rubber is very similar to that of natural rubber latex. Specific manufacturing techniques can alter the physical properties of natural rubber to suit certain specifications such as dimensions and tightness.

Natural rubber latex is the white sap that comes from the rubber producing tree, hevea brasiliensis. This forms the basis of all rubber based products although specific refinements and compounding processes transform it into varying physically altered specifications. Natural rubber latex has extreme elongation, tear resilient and durability properties.

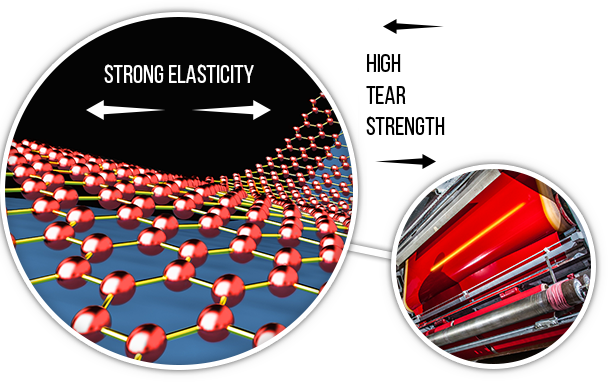

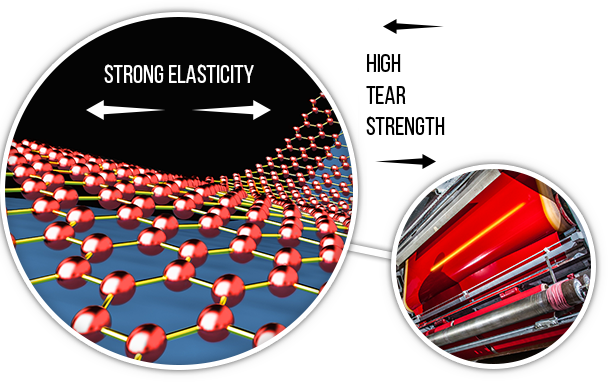

Synthetic rubber is the term for artificially moderated rubber which has been mainly synthesised from petroleum by products. Synthetic rubber is commonly known for its elasticity.

How long does delivery take?

Generally our delivery lead times are between ? and ? days, although this does vary depending on the shipping location.

Bespoke orders can also alter lead times depending on certain specifications. For more information on our lead times, or to ascertain a set lead time please call ? or email ?

How much are your products?

As a white label company, many of our products vary depending on the bespoke client specification. Although we do offer standard products and packaging options, we do not list these on our website as again prices can vary depending on batch ordering and locations. If you are looking to obtain a price for any of our products, please email ? or call ? and we will be happy to assist.

How is rubber manufactured?

Rubber is manufactured in various ways depending on the application it is to be used for.

Four D manufacture a range of natural rubber, latex and synthetic products, each in varying controlled environments. See our Four D technology page for more information on our processes.

What’s the difference between natural rubber, natural rubber latex and synthetic rubber?

Natural rubber is the outcome of dried natural rubber latex which has been compounded and processed. The chemical make up of natural rubber is very similar to that of natural rubber latex. Specific manufacturing techniques can alter the physical properties of natural rubber to suit certain specifications such as dimensions and tightness.

Natural rubber latex is the white sap that comes from the rubber producing tree, hevea brasiliensis. This forms the basis of all rubber based products although specific refinements and compounding processes transform it into varying physically altered specifications. Natural rubber latex has extreme elongation, tear resilient and durability properties.

Synthetic rubber is the term for artificially moderated rubber which has been mainly synthesised from petroleum byproducts.

Synthetic rubber is commonly known for its elasticity.